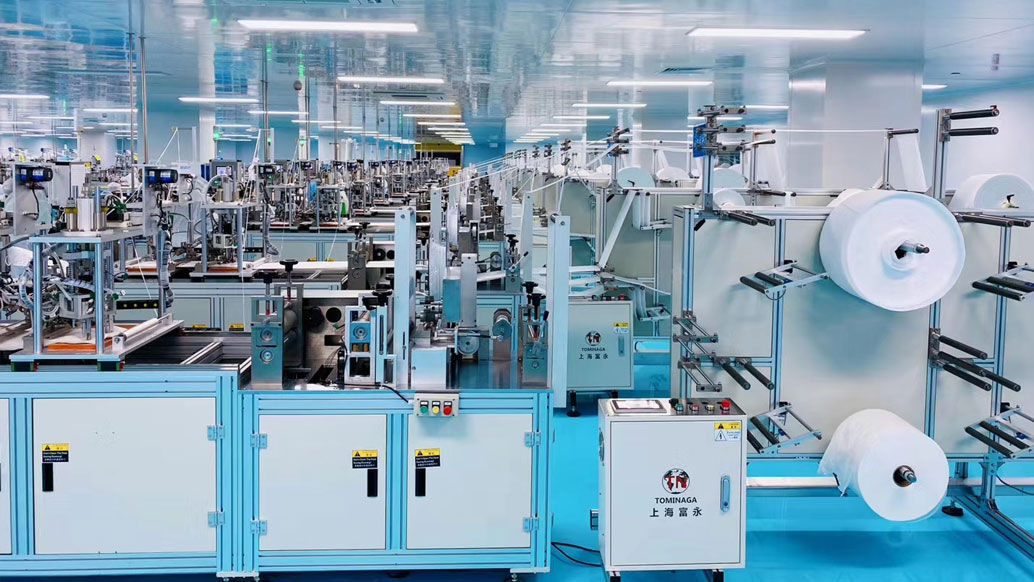

The highest standards apply at every level

At NeuiTec factory, people are at the heart of everything we do and everything we make. That means considering not only those who will use a product, but also those who help build it. we hold ourselves to the highest standards to produce the products with highest quality.